Why Trucks Use Air Brakes Instead of Hydraulic Brakes

Ever wonder why those massive trucks on the highway don’t just rely on regular car brakes? Imagine trying to stop an 80,000-pound beast with the same system your sedan uses! That’s where air brakes come into play. Designed specifically for heavy-duty vehicles, air brakes offer reliability, strength, and fail-safe mechanisms that hydraulic systems just can’t match. But here’s the kicker: brass fittings play a critical role in ensuring these air brake systems run smoothly.

Let’s break down how air brakes work, why trucks swear by them, and why brass is the unsung hero of the system.

- Strength and Durability: Air brakes are tough. They’re designed to handle the immense weight of trucks that can easily weigh more than 80,000 pounds. Regular hydraulic brakes would overheat or wear out under these extreme conditions(Showroomex).

- Fail-Safe System: One major advantage of air brakes is their fail-safe mechanism. If the system loses air pressure, the brakes automatically engage, stopping the vehicle. It’s like having an emergency backup that kicks in when you need it most(Saviors Repair)(RxMechanic).

How Air Brakes Work: The Basics

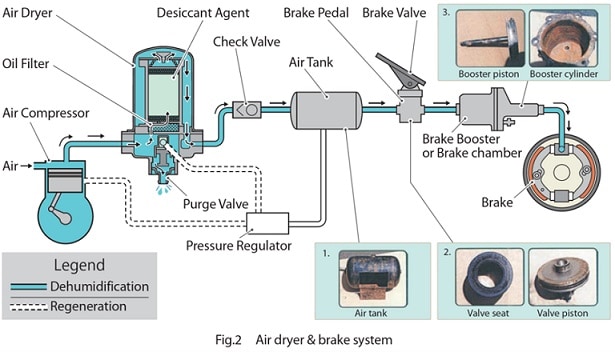

Air brakes might sound complex, but they operate on a simple principle: compressed air is used to create the pressure needed to stop the vehicle. Here’s a quick overview of how they work:

- Compression: The truck’s engine powers an air compressor, which fills storage tanks with compressed air.

- Application: When the driver presses the brake pedal, air is released from the tanks and travels through the brake lines.

- Braking: The air pushes the brake pads or shoes against the wheels, generating the friction needed to slow down the truck(Showroomex)(RxMechanic).

Air brakes are highly efficient, but they need to be properly maintained to ensure they perform reliably. This is where brass comes into play.

Brass: The Unsung Hero of Air Brakes

You’re probably familiar with the term brass, but you might not realize how important this metal is in keeping your truck’s air brake system running smoothly. Brass is the go-to material for air brake fittings because of its durability, corrosion resistance, and ability to handle high pressure.

Why Brass? Corrosion Resistance and Strength

Brass is essential in air brake systems for several reasons:

- Corrosion Resistance: Trucks are exposed to harsh environments, from rain to snow to salty roads. Brass is highly resistant to corrosion, which ensures the brake fittings don’t degrade over time(Baltic Truck)(TrustBrass).

- Strength: Brass is tough enough to withstand the high pressure generated by the air compressor. It also maintains a tight seal, which is crucial for preventing leaks in the system.

- Cost-Effective: Brass offers a balance of durability and affordability, making it the ideal material for air brake fittings(Baltic Truck).

Brass vs. Other Materials in Air Brakes

You might wonder why brass is preferred over materials like steel or aluminum. The answer lies in the unique combination of strength, machinability, and corrosion resistance. Brass fittings are also easier to manufacture into complex shapes, allowing for tight, secure seals in the brake system.

For more information on how brass is used in truck brake systems and other industrial applications, check out our in-depth guide at https://mbpindia.com/brass-adapters-and-fittings/.

Preventing Air Brake Failures with Proper Maintenance

Even though air brakes are incredibly reliable, they still need regular maintenance. One common issue is the buildup of water vapor in the air tanks, which can freeze in cold conditions and affect brake performance. To combat this, trucks are equipped with air dryers and moisture traps to remove water from the system. Regular checks and maintenance of brass fittings are also essential to ensure that the air brake system operates smoothly(RxMechanic).

Conclusion: Brass and Air Brakes — A Perfect Pair

In conclusion, air brakes are the preferred system for heavy-duty trucks because of their reliability, strength, and fail-safe mechanisms. And while air brakes get all the attention, brass fittings are the silent champions ensuring the entire system holds together under high pressure.

Next time you see a truck safely come to a stop, you’ll know it’s not just the air brake system working its magic—it’s the reliable brass fittings that help keep everything running smoothly. For more on the role of brass in truck air brake systems, visit https://mbpindia.com/brass-adapters-and-fittings/.

Sources:

- www.internationalusedtrucks.com/how-do-air-brakes-work/

- www.ril-ctcam.com/en/components-of-truck-air-brake-system/

- http://www.youtube.com/watch?v=rLLndBULsBU&t=63s

- http://www.youtube.com/watch?v=uZ7lu064YEU&t=190s

Tags: #AirBrakes #BrassFittings #TruckSafety #HeavyDutyTrucks #Engineering #Transportation #TeamMBP #MBPIndia

Check out more articles from us: Export Insurance: Essential Protection or Unnecessary Expense? 🤔

Hi! Could I get your advice? A call or a WhatsApp message would be perfect. Call me on Whatsapp for quick communication