Are you a homeowner looking to protect your plumbing system from corrosion and leaks? If so, understanding the importance and uses of dielectric unions is essential. These small devices play a critical role in preventing galvanic corrosion, which occurs when different types of metal come into contact with each other. In this comprehensive guide, we will explore everything you need to know about dielectric unions and how they can benefit your plumbing system.

Dielectric unions are specially designed fittings that create a barrier between two different types of metals, such as copper and steel, in a plumbing system. By separating these metals, dielectric unions prevent electrolysis, which can lead to corrosion, leaks, and costly repairs. They are commonly found in water heaters, water softeners, and other plumbing appliances.

In this article, we will discuss the importance of dielectric unions in protecting your plumbing system, their various uses, and how to install and maintain them correctly. Whether you’re a seasoned homeowner or a first-time buyer, this guide will equip you with the knowledge to make informed decisions about using dielectric unions in your home.

The Importance of Dielectric Unions in Plumbing Systems

Dielectric unions are crucial components in residential plumbing systems. They act as a protective barrier between dissimilar metals, such as copper and steel, to prevent the occurrence of galvanic corrosion. Galvanic corrosion happens when metals with different electrode potentials are in contact with an electrolyte, like water. This process can lead to the deterioration of metal pipes, fittings, and appliances, ultimately causing leaks and costly damages.

Dielectric unions are specifically designed to interrupt the electrical current that occurs between two dissimilar metals, effectively breaking the circuit that leads to corrosion. By incorporating dielectric unions in your plumbing system, you can significantly extend the lifespan of your pipes and appliances, ensuring the integrity and efficiency of your home’s water distribution network.

Installing dielectric unions at key connection points in your plumbing system, such as between a copper pipe and a steel water heater, is a proactive measure to safeguard against corrosion. These unions not only protect your investment in plumbing infrastructure but also contribute to the overall safety and reliability of your water supply, minimizing the risk of unexpected leaks and water damage in your home.

How Do Dielectric Unions Work? 🤔

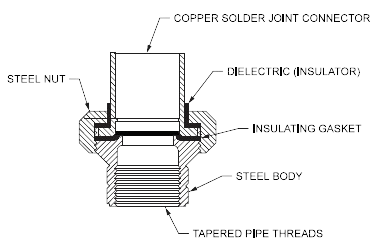

Dielectric unions operate based on the principle of isolating dissimilar metals to prevent the flow of electric current between them. The union consists of two distinct parts: a metal side that connects to one type of pipe, and a non-metallic side that connects to the other type of pipe. Between these two sides is a dielectric insulating material, typically made of plastic or rubber, which acts as a barrier to electrical conductivity.

When water flows through the pipes, any potential electrical charge that may develop due to the metal contact is blocked by the insulating material within the dielectric union. This interruption of the electrical circuit effectively stops the corrosion process from occurring, preserving the structural integrity of the plumbing system. Dielectric unions are a simple yet effective solution to a common problem in plumbing, providing long-term protection against galvanic corrosion and extending the lifespan of your pipes and fixtures.

Common Uses of Dielectric Unions in Residential Plumbing

Dielectric unions are commonly employed in various applications within residential plumbing systems. One of the most prevalent uses is in connecting different types of water heaters, such as combining a copper hot water line with a steel tank. By installing a dielectric union at this junction, homeowners can prevent the accelerated deterioration of the water heater components and ensure a reliable hot water supply for years to come.

Furthermore, dielectric unions are essential when connecting copper water supply lines to steel pipes or fixtures, as well as when integrating water softeners or filtration systems into the plumbing network. These unions play a vital role in maintaining the performance and longevity of these critical plumbing elements, reducing the likelihood of leaks, rust, and other issues associated with metal-to-metal contact.

In addition to protecting water heaters and supply lines, dielectric unions are also commonly found in outdoor faucets, irrigation systems, and any other areas where different metals come into contact. By strategically incorporating dielectric unions throughout your plumbing system, you can mitigate the risks of corrosion and preserve the overall efficiency and safety of your home’s water distribution infrastructure.

Benefits of Using Dielectric Unions

The utilization of dielectric unions in residential plumbing systems offers a multitude of benefits for homeowners. One of the primary advantages is the prevention of galvanic corrosion, which can lead to leaks, pipe failures, and extensive water damage if left unchecked. By installing dielectric unions at vulnerable connection points, homeowners can proactively protect their plumbing infrastructure and avoid costly repairs in the future.

Furthermore, dielectric unions help to maintain water quality by preventing the introduction of metal contaminants into the water supply. As corrosion occurs, metal particles can flake off into the water, compromising its purity and potentially posing health risks to occupants. By isolating dissimilar metals with dielectric unions, homeowners can ensure that their drinking water remains clean and free from harmful impurities.

Another significant benefit of using dielectric unions is the preservation of appliance efficiency and longevity. By reducing the corrosive effects of galvanic interaction, these unions help extend the lifespan of water heaters, fixtures, and piping systems, saving homeowners money on premature replacements and repairs. Overall, the investment in dielectric unions pays off in the form of enhanced system durability, water quality, and peace of mind for homeowners concerned about the integrity of their plumbing infrastructure.

Different Types of Dielectric Unions and Their Applications

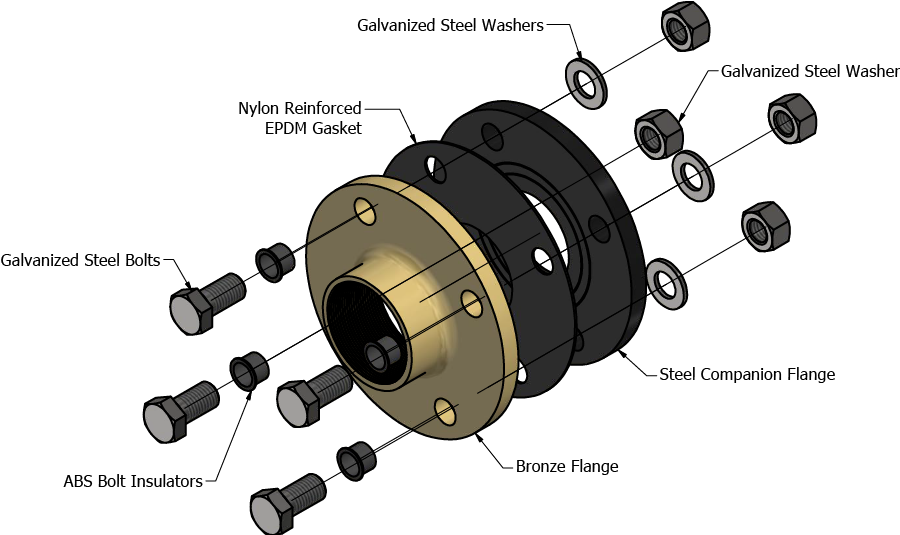

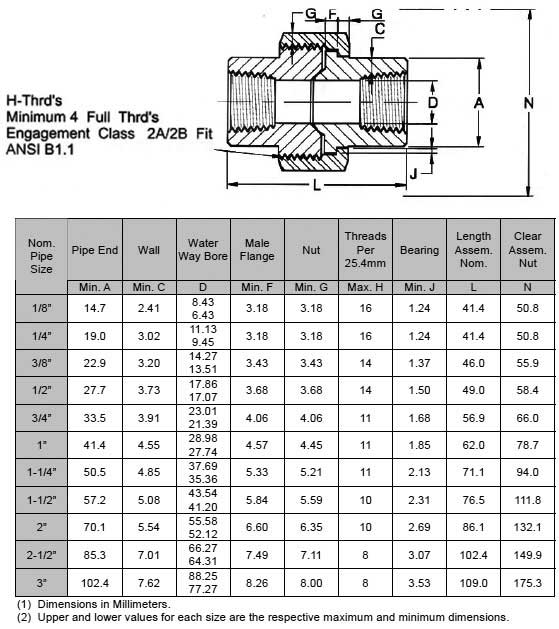

Dielectric unions are available in various configurations to suit different plumbing requirements and applications. The most common types include standard dielectric unions, union tees, and dielectric nipples, each serving a specific function in the plumbing system. Standard dielectric unions are used for connecting two pipes of different materials, while union tees allow for branching connections with dielectric isolation at multiple points.

Dielectric nipples, on the other hand, are short threaded pipes with dielectric insulation, ideal for connecting water heaters, faucets, or other fixtures to plumbing lines. These specialized unions come in different sizes and materials to accommodate specific installation needs, ensuring compatibility with various pipe materials and connection types. By selecting the right type of dielectric union for each application, homeowners can effectively protect their plumbing system from corrosion and maintain optimal performance over time.

Installation and Maintenance Tips for Dielectric Unions

Proper installation and maintenance of dielectric unions are essential to ensure their effectiveness in protecting your plumbing system. When installing a dielectric union, always follow the manufacturer’s guidelines and recommendations to achieve a secure and leak-free connection. Make sure to clean and deburr the pipe ends before assembly, and use appropriate tools to tighten the union fittings to the specified torque values.

Regular inspections of dielectric unions are crucial to detecting any signs of wear, corrosion, or leaks that may compromise their functionality. Check for visible damage or discoloration on the union components, as well as any indications of water seepage around the connection points. If any issues are identified, promptly replace or repair the affected union to prevent further damage to the surrounding pipes and fixtures.

Additionally, flushing the plumbing system periodically can help remove sediment and mineral buildup that may affect the performance of dielectric unions. Flushing the system with clean water at regular intervals can prolong the lifespan of these protective devices and maintain the efficiency of your plumbing infrastructure. By implementing proper installation and maintenance practices, homeowners can maximize the benefits of dielectric unions and ensure the long-term integrity of their plumbing system.

How to Choose the Right Dielectric Union for Your Plumbing System

Selecting the appropriate dielectric union for your plumbing system involves considering several factors to ensure compatibility and optimal performance. Start by identifying the types of metals in your plumbing network that require isolation, such as copper, steel, or brass. Determine the size and thread specifications of the pipes you need to connect, as well as the pressure and temperature ratings for the application.

When choosing a dielectric union, look for high-quality materials that offer superior corrosion resistance and durability, such as stainless steel, brass, or reinforced plastic. Consider the specific installation requirements, such as the need for flanged or threaded connections, and ensure that the union meets industry standards for safety and reliability. Consulting with a professional plumber or knowledgeable supplier can help you select the right dielectric union for your specific plumbing needs.

It is also essential to verify the warranty and maintenance recommendations provided by the manufacturer to understand the expected lifespan and care instructions for the dielectric union. By investing in a high-quality, properly sized dielectric union that meets your plumbing system’s requirements, you can effectively protect your pipes and appliances from corrosion and ensure the long-term efficiency of your home’s water distribution system.

Common Issues and Troubleshooting with Dielectric Unions

Despite their protective benefits, dielectric unions may encounter issues over time that require troubleshooting and potential repairs. One common problem is the development of leaks at the union connections, which can result from improper installation, corrosion, or wear of the sealing components. If you notice any leaks around a dielectric union, first shut off the water supply to the affected area and inspect the union for visible damage or loose fittings.

Another issue that may arise with dielectric unions is reduced water flow or pressure, which could indicate a blockage or sediment buildup within the union. In such cases, flushing the plumbing system or disassembling the union for cleaning may help restore normal water flow and performance. Regular maintenance and inspection of dielectric unions can help identify these issues early on and prevent more significant problems down the line.

If troubleshooting efforts fail to resolve the issue with a dielectric union, or if you suspect significant corrosion or damage to the union components, it may be necessary to replace the union entirely. Contact a licensed plumber or professional service provider to assess the situation and recommend the best course of action to address the problem effectively. Prompt attention to malfunctioning dielectric unions can prevent water damage and ensure the continued protection of your plumbing system.

Conclusion: The Role of Dielectric Unions in Protecting Your Plumbing System

In conclusion, dielectric unions play a vital role in safeguarding your plumbing system against galvanic corrosion and preserving the integrity of your pipes, fixtures, and appliances. By creating a barrier between dissimilar metals, these small yet essential devices prevent the destructive effects of electrolysis and extend the lifespan of your plumbing infrastructure. Whether used in water heaters, supply lines, or other critical connections, dielectric unions offer homeowners peace of mind and long-term protection from leaks, rust, and costly repairs.

Understanding the importance and uses of dielectric unions empowers homeowners to make informed decisions about their plumbing system’s maintenance and longevity. By following proper installation practices, selecting the right type of union for each application, and conducting regular maintenance checks, homeowners can maximize the benefits of these protective devices and ensure the efficient operation of their water distribution network. With dielectric unions as an integral part of your plumbing system, you can enjoy reliable performance, clean water, and lasting durability for years to come.

A luvbet é confiável, galera? Já ouvi falar bem, mas queria saber a opinião de vocês antes de colocar meu dinheiro lá. Alguém já sacou dinheiro de boa?

Perfect work you have done, this website is really cool with fantastic information.